Products

-

Cobalt Based

Cobalt-based alloys are frequently used in various fields where high wear-resistance is needed, including aerospace, cutlery, medical apparatus and instruments. It is commonly used for dental bridge, dental crown, false teeth due to excellent resistant properties, high melting points and incredible strength at high temperatures

Read More -

Titanium & Titanium Alloy

The high strength, low weight ratio and outstanding corrosion resistance inherent to titanium and its alloys has led to wide and diversified range of successful applications which demand high levels of reliable performance in surgery and medicine as well as in aerospace, automotive, power generation, chemical plant, sports, oil and gas extraction, and other major industries.

Read More -

Iron Based

Excellent mechanical and corrosion resistance properties and cost-effectiveness to stainless steel has led to a wide variety of applications in the automotive, medical and general industry markets, used to produce a range of products, including surgical tools, metallic filters, pumps, impellers and structural automotive parts.

Read More

Application

-

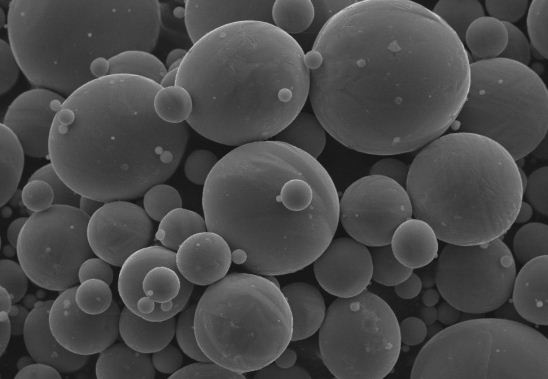

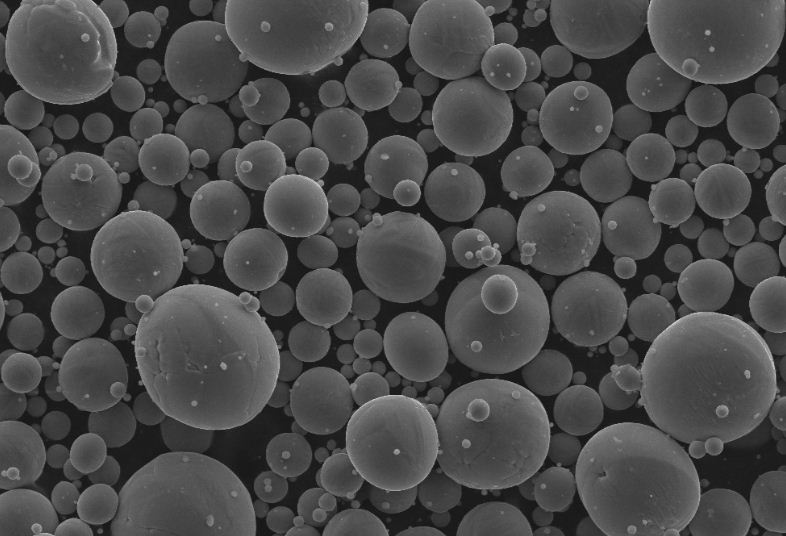

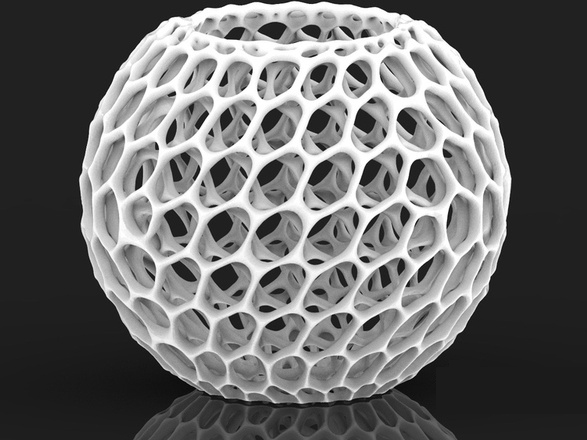

Additive Manufacturing (AM)

3D printing, also known as additive manufacturing, is one of many various processes used to synthesize a three-dimensional object. In 3D printing, successive layers of material are applied under computer control. These objects can be of almost any shape or geometry, and are produced from a 3D model or other electronic data source. A 3D printer is a type of industrial robot. 3D printing in the term's original sense refers to processes that sequentially deposit material onto a powder bed with inkjet printer heads. More recently, the meaning of the term has expanded to encompass a wider variety of techniques such as extrusion and sintering-based processes.

Read More -

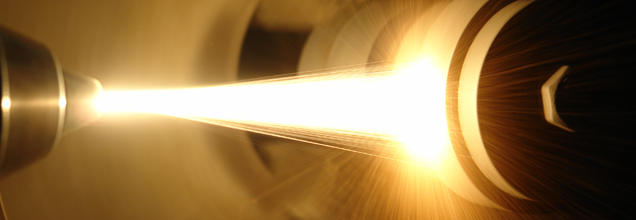

Thermal Spraying

Thermal spraying techniques are coating processes in which melted (or heated) materials are sprayed onto a surface. The "feedstock" (coating precursor) is heated by electrical (plasma or arc) or chemical means (combustion flame). Thermal spraying can provide thick coatings (approx. thickness range is 20 micrometers to several mm, depending on the process and feedstock), over a large area at high deposition rate as compared to other coating processes such as electroplating, physical and chemical vapor deposition

Read More -

Metal Injection Molding (MIM)

Metal injection moulding (MIM) is a metalworking process by which finely-powdered metal is mixed with a measured amount of binder material to comprise a “feedstock” capable of being handled by plastic processing equipment through a process known as injection mold forming. The molding process allows complex parts to be shaped in a single operation and in high volume. End products are commonly component items used in various industries and applications. The nature of MIM feedstock flow is defined by a physics rheology.

Read More